By Kolin Hawkins | Drive Team Coach

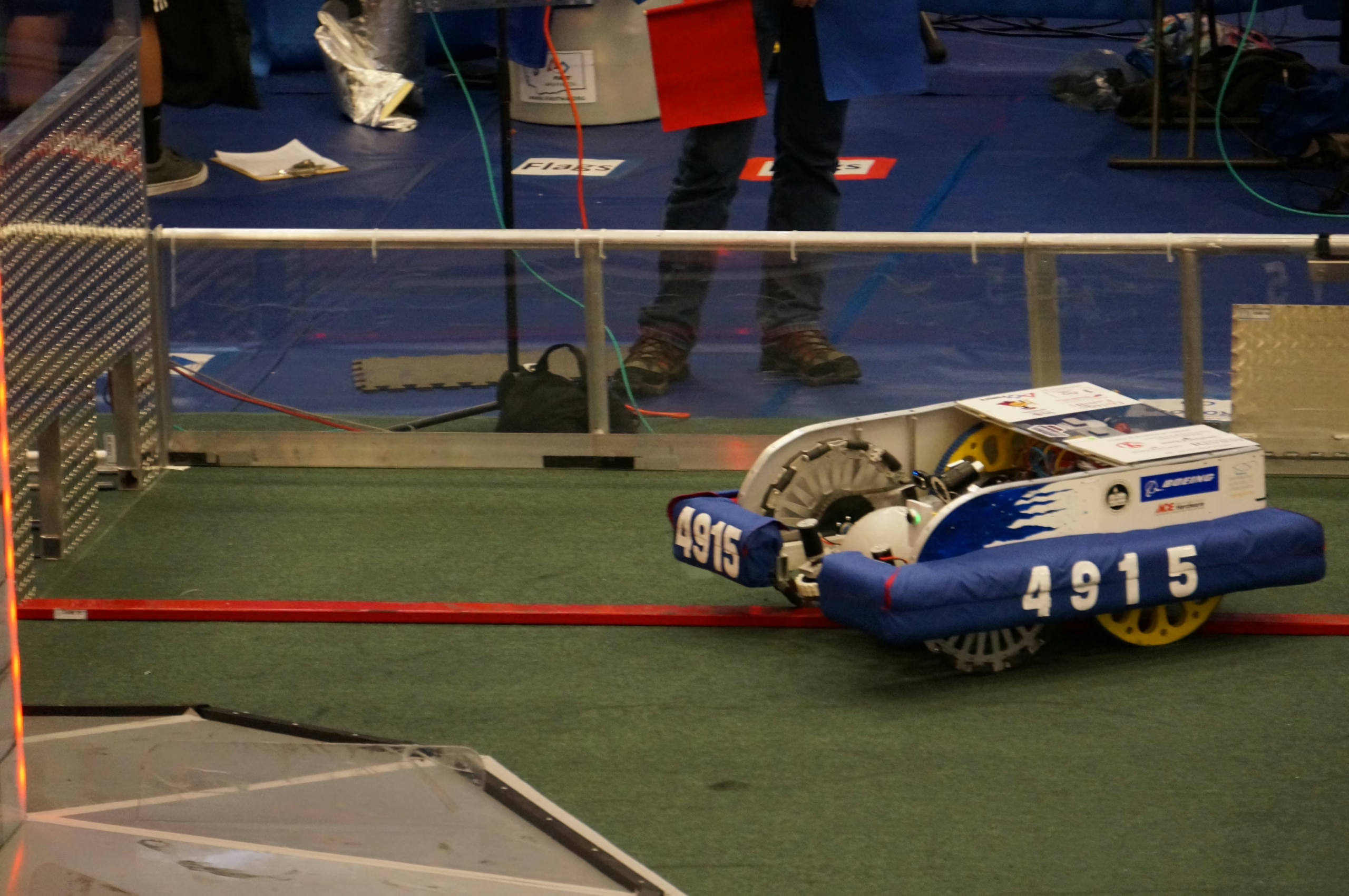

The Glacier Peak District Event, as our Mentor Dana Batali so aptly described, was an epic saga of medieval proportions for  Spartronics 4915. We wanted to provide a full account to anyone who was there experiencing these unusual circumstances with us, or those of you watching at home or video recordings. Our goal here is to do two things: First, to provide transparency about what happened and, to the best of our collective knowledge, why it happened, and Second, what we have done to fix our robot ARES.

Spartronics 4915. We wanted to provide a full account to anyone who was there experiencing these unusual circumstances with us, or those of you watching at home or video recordings. Our goal here is to do two things: First, to provide transparency about what happened and, to the best of our collective knowledge, why it happened, and Second, what we have done to fix our robot ARES.

The good news is we are confident that we have addressed the critical issues that impacted our ability to perform consistently as well as the issues that ultimately caused our Spartronics robot to miss a match. This was a first in our team’s three-year history, which is remarkable considering we went all the way to Worlds these first two years.

Here is a full recap of the events at Glacier Peak, and at the end, details on what we did during our six hours of un-bag time this week.

What went wrong at Glacier Peak:

What we have done:

- We have relocated our electronics from being in a vertical position inside the robot to a horizontal layout, which improves significantly better access for maintenance and repair.

- We located our breaker to move it away from the polycarbonate top, which was accidentally turning off the robot when a large shock caused the polycarbonate to flex and press the breaker button.

- We added wire ferrules to critical connections between the radio and the VRM so that power loss to the radio will be avoided. Previously, critical wires were getting disconnected.

- We added a suspension system to the robot to cushion its landing after it crosses defenses.

- Our turn button on the joystick was fixed, which allows us to more accurately turn the robot.

- We added code that allows us to spin the flywheels at a better speed to more effectively shoot low goals. Previously, the intake speed and the shoot speed where the same and the low goal often bounced out.

What has changed:

- We will not be shooting high goals at Mount Vernon, as we made adjustments to the pivot point on our intake, which will give us more stability and allow us to better control scoring low goals.

- We added a Portcullis lifter/Cheval de Frise manipulator, which we have not tested in a match, but are hopeful will help us assist with breeching these defenses.

We are excited about Mount Vernon this weekend and are ready to answer any questions other teams may have.